%%date%% %%sep%% %%sitename%%

Working on a Cummins engine without knowing its fault codes makes your job nearly impossible. We’ll go over what fault codes are, well-known Cummins issues that cause them, and how to clear these codes.

What Are Cummins Fault Codes?

Fault codes indicate your engine is experiencing a problem. A modern diesel engine is full of different circuits and sensors, and each one of these parts gives off a specific reading and voltage signal.

Source: Reddit

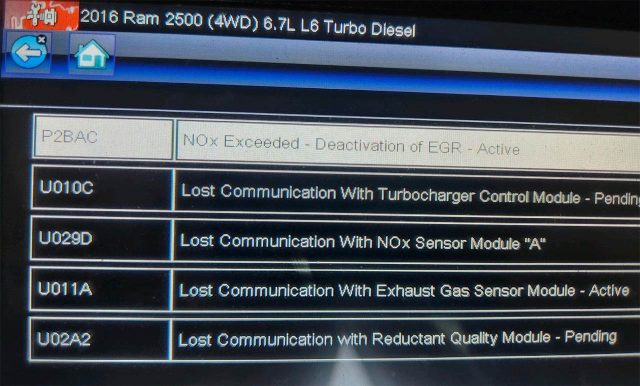

Each engine also has an Electronic Control Module (ECM) that’s constantly monitoring your engine while it’s running. If your engine diagnostics go over/under their expected value, the ECM logs a fault code. There are three different types of fault code statuses:

Inactive: If it happens at a time outside of diagnostics, then it’s inactive.

Active: If the error pops up during diagnosis, then it’s an active fault.

Pending: A pending code has not been cleared.

Pending codes can also be intermittent faults: faults that need to be “seen” in at least two warm-up cycles before they’re set to active. For example, a code can be active after the problem has been repaired. Sometimes several drive cycles are necessary to clear a code’s active status.

There are dozens –potentially hundreds– of fault codes out there, and codes change from engine to engine. When you’re searching for fault codes, you must be looking for information specific to your engine.

For example, a pre-EGR engine from 2002 and a 2007-2010 engine with DPF will have a different list of ISX fault codes. The 111 fault code on the 2002 engine stands for the Electronic Control Module, while the same code on the later engine is a specific error: ECM Critical Internal Failure.

New engines typically have more detailed fault codes. Newer engine models will also have codes that didn’t exist in previous models.

Source: Reddit

How To Clear Cummins Fault Codes

Once you’ve made the necessary engine repairs you can clear the fault codes. To do this, you’ll need a diagnostic tool and software. Connect a code reader tool to your ECM and navigate to the “fault codes” tab.

You should be able to click on each code individually or remove them all at once with an “erase all faults” option. Follow the onscreen instructions and turn off the ignition key when finished. Press the appropriate button on your diagnostic tool and turn the key back on.

The above procedure doesn’t work with every powertrain control module (PCM) software. If you can’t clear fault codes this way, you’ll need to clear them using an Onboard Diagnostics scanner (OBD-II).

Follow these steps to clear the Cummins fault codes with a scanner:

Close the doors, then insert the key into the ignition

Cycle the key five times, switching it from “off” to “run” without actually cranking the engine

On the fifth cycle, leave in run

This process will clear any pending or active codes. While following these steps, remember: the “run” position is two clicks of the key. The “accessory” position is only one key click.

Cummins Engine Issues

Cummins engines are usually reliable, but no engine is perfect; there are some common malfunctions to look out for. Some of these issues are specific to certain Cummins models as well.

Lift pump – The lift pump is part of a complex fuel injection setup. When this part is about to fail, there are no obvious signs, and when the lift pump weakens, the rest of the injection system compensates for it. This puts the system under incredible strain.

Killer Dowel Pin – A combination of engine vibrations and temperature fluctuations can cause steel dowel pins to shake loose and cause damage, a phenomenon known as the “killer dowel pin.” This problem is mainly found in 5.9-liter 12 or 24-valve engines from 1989 to 2002.

Source: Reddit

Once the pin is knocked loose, it can get stuck in one of four places:

The timing gear housing and cam gear, but this doesn’t damage the housing

In the oil pan, this also doesn’t damage the housing

Timing gear and cam gear which does damage the housing

The cam and injection pump gears, which can kill the engine completely

Fortunately, diesel parts shops like ProSource Diesel sell KDP (Killer Dowel Pin) kits to fix and prevent this issue from happening.

12-Valve Killer Dowel Pin KDP For 94-98 5.9L Dodge Cummins 24V

KDP Killer Dowel Pin For 98.5-02 5.9L Dodge Cummins 24V

Misfiring – Misfiring is a common issue for most diesel engines. Usually, the engine’s fuel injectors are to blame. Fuel injectors that are leaky or stuck cause fuel to leak into the engine oil. This problem may also be the result of an electrical malfunction.

Cracked Engine Block – This is a less common issue, but still one to watch out for. Cracked engine blocks pop up most often on engines between 1999 and 2002 with a 53 stamp on the block. The thin water walls crack and leak coolant into the engine. If not caught early enough, the entire block needs replacing. Because of this issue, avoid towing and cold-running on 53-stamp engines.

Source: Reddit

These are just some of the most common issues in Cummins engines; other problems may crop up. To keep any diesel engine in its best shape, follow recommended maintenance schedules and stay on top of preventative repairs and replacements.

Cummins 6.7 Liter Maintenance

When following a maintenance schedule, it’s important to address issues ASAP, especially if you’re using your truck under severe driving conditions.

Any of the following count as severe driving conditions:

Excessive idling

Frequent short trips that keep the engine from reaching full operating temperature

Driving in dusty conditions

Off-road driving or conditions that require 4WD

Service intervals are usually the maximum recommended time or mileage before service. You can always have maintenance done sooner.

Here are some examples of routine maintenance tasks for a 6.7-liter Ram truck diesel:

15,000 miles or 12 months: replace engine and chassis mounted fuel filters

30,000 miles or 24 months: replace engine air filter (check your filter regularly at oil changes and replace as necessary)

60,000 miles or 48 months: replace transfer case fluid (for trucks under severe driving conditions, replace every 30,000 miles or 24 months)

67,500 to 75,000 miles: replace crankcase ventilation filter or as indicated by the display (2007.5 2018 engines should be done at 67,500 and 2019+ engines at 75,000 max)

100,000 miles: replace serpentine drive belt (inspect the belt during oil changes and replace it if necessary)

Oil changes on 2007.5 – 2019 Ram truck engines should have their oil changed every 7,500 miles, six months, or 500 hours –whichever comes first. Pay attention to your oil change indicator.

Further reading:

The 6.7 Cummins Parts Most Likely to Need Replaced

The Best Cummins 6.7 Upgrades

Source: Reddit

Cummins 5.9 Liter Maintenance

The maintenance intervals between the 12-valve and 24-valve versions of the second-generation Dodge truck engine are very similar. They also use many of the same Cummins parts. The service intervals of a Dodge diesel truck depend on its usage: if it falls under any of the severe use considerations then it should be serviced more often. Regular service tasks include:

Inspect steering and suspension system and parts for wear

Inspect exhaust system

Check all fluid and oil-holding components for leaks

Check the truck’s parking spot for evidence of leaks

Inspect brake hoses

Rotate tires and check for damage

Check fluid levels

Check engine air filter

Drain water from the fuel filter (should be done monthly)

Oil changes for the 12-valve under normal operating conditions should take place every 6,000 miles or six months. If the engine is under severe operating conditions, change the oil every 3,000 miles or three months.

Under normal conditions, the 24-valve engine type can go 7,500 miles or six months without an oil change. Under severe conditions, change the oil every 3,750 miles/three months.

Intervals for changing the fuel filter are the same between the 24-valve and 6.7-liter engines. 12-valve engines should have their filter replaced every 12,000 miles or 12 months, whichever comes first, regardless of operating conditions.

Further reading: The 5.9 24V Cummins Parts Most Likely to Need Replaced

When it comes to repairing your heavy-duty Ford truck, Dodge truck, or Chevy truck, ProSource Diesel has all the reliable and hard-to-find diesel truck parts and kits you need to keep your rig in good shape. We also stock a wide selection of Powerstroke parts and Duramax parts.

%%excerpt%%

The post How to Clear Cummins Fault Codes appeared first on Prosource Diesel.

%%category%%

%%tag%%