%%date%% %%sep%% %%sitename%%

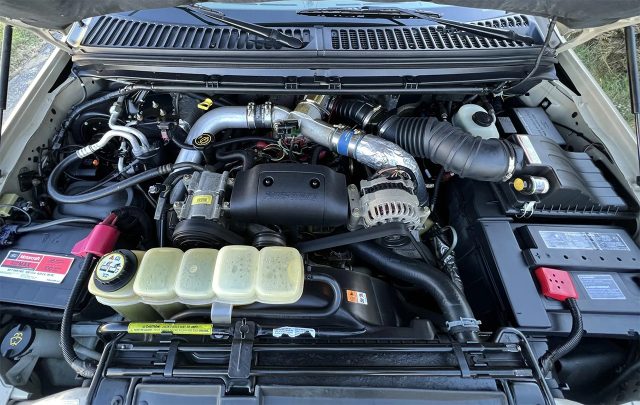

The 7.3 Powerstroke is considered one of the most legendary diesel engines. Its main claim to fame, besides its legendary reliability, is that it is the largest diesel engine to be put in consumer trucks and produced in high numbers.

The 7.3 Powerstroke was made between 1994 and 2003. However, due to some tweaks over the years, if you’re looking for 7.3 Powerstroke parts, you’ll want to use the following breakdown as a guide:

1994-1997 Powerstroke parts

Early 1999 Powerstroke parts

1999.5-2003 Powerstroke parts

Image courtesy and copyright of Bring a Trailer

Despite its highly-vaunted reliability, coming in only second to the 5.9-liter Cummins, the 7.3 Powerstroke did have some problems. Some of these problems were also fairly common, and they occurred in all of the production years since the overall engine was the same.

ProSource Diesel takes a look at some common problems with Powerstroke parts and ways to fix them.

Injection Pressure Regulator Valve (IPR)

The IPR valve on the 7.3 Powerstroke has a tendency to stick, but other problems include a bad sensor or damaged wires. You can find the IPR valve near the valley of the High-Pressure Oil Pump.

When you find it, check that the nut on the back of the IPR sensor is still tight, and look for loose or damaged wires. You can rebuild an IPR valve for quite cheap. A new one will cost in the range of $140 to $300. Don’t use thread sealer as there’s an opening in the threads that must not be closed.

Injector Driver Module (IDM)

The IDM on a 7.3 Powerstroke is easy to locate by looking at the driver’s side fender. The IDM switches the injectors on and off and gets commands from the Powertrain Control Module (PCM). The main problem with the IDM is that it can become contaminated with water, which leads to failure. IDM failure can result in a rough idle and the truck may not start. Diesel truck parts to rebuild the IDM are typically inexpensive, but a new one might cost around $300.

Cam Position Sensor (CPS)

A worn or damaged CPS can cause the Powerstroke engine to cut out or die completely. It might not start again until it has sat for a time or the batteries are reset. An issue with the CPS is one of the most common problems on the 7.3 Powerstroke.

On the Old Body Style, the tachometer will move while cranking if the CPS is good. If it doesn’t move, then the CPS is the problem. Fortunately, a new CPS for the 7.3 Powerstroke is one of the more inexpensive diesel parts to replace.

Under Valve Cover Harness Connectors (UVCH)

Problems with the UVCH connectors are another common issue with the 7.3 Powerstroke. These connectors might come loose or short out, and that can cause the engine to run rough. Specific symptoms of this are engine-loping, sputtering, and dying outright.

These connectors are under the valve cover, so if you decide to replace them, you should also replace the valve cover gaskets. The entire kit for replacing the connectors and valve cover gaskets is typically quite affordable.

Fuel Filter Clogs

This is a pretty common problem with the 7.3 Powerstroke, but it’s also pretty easy to fix. Symptoms include long cranking or power loss. It’s important to check and replace the fuel filter regularly.

Lift Pump Failure

If you have a bad 7.3 powerstroke lift pump, your engine won’t start. You can check if this is the reason behind a no-start by checking the fuel bowl before and while cranking. If there’s no fuel in the bowl, fill the bowl with clean fuel. If the engine starts, then you need to replace the 7.3 lift pump.

Injector Control Pressure Sensor (ICP)

If the ICP sensor is failing, it may cause the engine to cut in and out while running. To see if this is the problem with a rough-running engine, check for oil in the ICP connector. If you see oil, then the ICP sensor is going out or bad.

You can also unplug the ICP sensor temporarily to see if that improves the issue. If it does, then the ICP sensor for the 7.3 is likely to blame.

Overheating

This is a pretty general issue on the 7.3 Powerstroke, but the main reasons for it are usually the thermostat or the 7.3 water pump. Both Powerstroke diesel parts are easy to source and replace in most cases.

Diesel Fuel Heater Problems

The fuel heater on the 7.3 Powerstroke can short out by blowing maxi fuse #22, which then disables the PCM. To fix this, disconnect the fuel heater, replace the fuse, and try to start it again. It’s a good idea to simply carry spare fuses to make this easy fix if it happens.

Exhaust Back Pressure Valve (EBPV)

The EBPV is a butterfly valve located on the turbocharger. The valve’s function is to reduce the time that the engine needs to get to normal operating temperature. If the valve sticks closed, it can cause hot exhaust air to accumulate inside the engine. The system also may leak oil, which might require a rebuild of the entire EBPV system.

Overall, the 7.3 Powerstroke is quite a reliable diesel engine, and even the issues listed here are generally easy to fix. As your engine gets older, it’s always a good idea to replace stock parts with Powerstroke performance parts and upgrades for the best results.

Rely on ProSource Diesel for performance and aftermarket 7.3 Powerstroke parts to repair common problems with this engine. Aftermarket Ford Powerstroke parts often meet or exceed OEM standards, and we carry the widest selection. That’s why we are where diesel repair shops shop for diesel truck parts.

%%excerpt%%

The post 7.3 Powerstroke Problems appeared first on Prosource Diesel.

%%category%%

%%tag%%