The Ford Cosworth YB engine is one of the most receptive engines to tuning that Ford has ever produced. Let’s take a look at how to extract those impressive power figures from the mighty Cossie motor…

The story of the Ford Cosworth YB engine starts long before the arrival of the Sierra Cosworth in 1985. Although that was the first time we saw it in all its road-going glory, the tale starts at the end of the 1970s.

Ford Cosworth YB Engine History

Despite dominating circuit racing and rallying throughout the 1970s, Ford’s grip on motorsport was loosening, and fast. Even the mighty DFV Formula One engine was losing out to modern turbocharged units.

The misery was blatant during a Ford VIP visit to the 1983 British Grand Prix at Silverstone, where a touring car battle supported the main event. Dismayed Blue Oval bigwigs Stuart Turner and Walter Hayes witnessed a series of Capris being humiliated by V8 Rover SD1s, with only Richard Longman’s class-winning Escort RS1600i easing the pain.

Turner and Hayes agreed a plan of action. This coincided with a tour of Cosworth’s premises in the company of American Blue Oval bosses Ed Blanch and Jim Capolongo. Yes, the aim of the visit was to check out the firm’s forthcoming Formula One engine. But how could they ignore a Pinto/T88 bottom end equipped with an aluminum, 16-valve cylinder head, which accidentally-on-purpose found itself the center of attention…

By the autumn of 1983, Cosworth went ahead with SOHC Pinto/T88 cylinder block based 2.0-litre engine. However, unlike the original naturally-aspirated conversion, this time it would include a turbo. It also needed to produce 180bhp in road trim and more than 300bhp when race-tuned.

But when it was found that 200bhp-plus was easy to achieve for road cars, this was also agreed. Experience later proved that race engines could produce up to 350bhp with relative ease. However, the big leap to 550bhp came with the RS500-style YBD power unit in 1986.

YBD Cosworth Engine

Initially coded YAA (YB, the production version came later – see Ford Cosworth YB Engine Codes), Mario Illien designed the original Pinto/16-valve conversion in 1983. It featured a very free-breathing cylinder head, a complex inlet manifold and long, tubular exhaust manifold; optimized for tuning to a 300-to-400bhp race engine – with full-throttle breathing in mind. Not much thought to drivability or refinement.

By the time ex-Weslake/ex-Lotus engineer Paul Fricker joined Cosworth at the end of 1983, Illien had left. Ford had by then awarded Cosworth a contract to complete the engine. It could also build a facility to produce at least 15,000 units.

This meant a complete redesign of the engine to make it suitable for road use. The conversion from race to road engine was never easy, and Fricker was always under pressure from Cosworth and Ford.

First there was the original contract of 15,000 engines. “At one time Ford talked of ending the project after the first 5000, but luckily they never did,” said Fricker.

Then there were changes with the fueling system. Originally contracted to Bosche, later went to Weber-Marelli of Italy following good experiences in F1. “There, we had three people who were working for just two clients – Ferrari and us,” said Fricker.

And then a load more work went into re-specifying the turbo. Fricker continued, “We did 400-to-500 hours on the performance test beds at Cosworth. The first time we put one on the durability bed, it lasted just 35 minutes before it blew up.”

The first YBA prototype started test-bed work in Northampton in June 1984. Although, the first engines and test cars didn’t go to Weber-Marelli in Italy until September 1984. Subsequently completed and signed off by mid-1985.

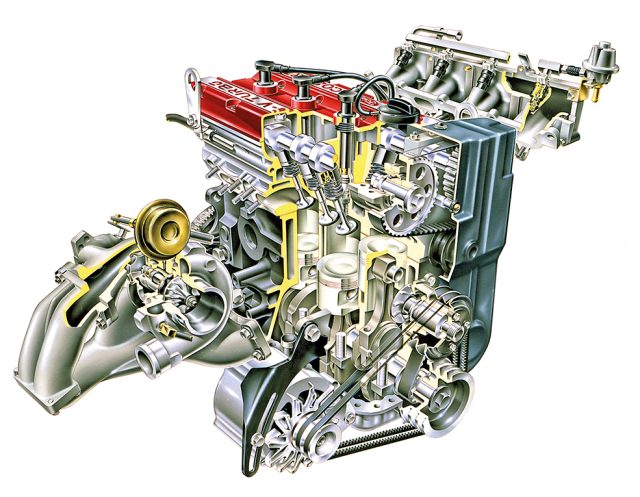

Compared with the basic Pinto, almost everything changed except for the cylinder block itself. This included new cylinder head and valve gear, new steel crankshaft, rods, pistons, and sump. The use of hydraulic valve lifters was a given. No subsequent engine tuner appears to have suffered from not being able to use conventional lifters.

“They did weigh more,” Fricker admits, “and there was always a small amount of air in the oil. We ended up changing the design so they couldn’t deflate overnight. On the original engine, if you had a hot engine, then left it parked for a week, the lifters would go down.”

Cosworth built a new factory at Wellingborough; series production started in 1985 and ended in 1995. Along the way, the YBB evolved. For the Nineties, the big change was to redevelop the engine for use in the EsCos, originally as YBT and (from 1994) as YBP. The YBT engine might have looked similar, but had advanced in various ways. This was notably with a hybrid T03/T04B Garrett turbocharger. It was really too big for road cars, but Ford Motorsport needed a large enough unit homologated to make the Escort Cosworth the rally winner it became.

Blue painted cam covers instead of the Sierra Cosworth 4×4’s green identify the YBT. Paul Fricker explained: “We needed yet another color, and we thought it looked nice. We didn’t consult Ford Design until it was too late to get into an artistic argument.”

With 227bhp at 6250rpm, the YBT engine was extremely flexible. Naturally it ran on unleaded fuel, and an exhaust catalyst was standard. Finally, in 1994, the YBT gave way to the YBP. This one had a smaller T25 turbo, Ford’s EEC-IV electronic engine management, and a restyled camshaft cover. It was more drivable, just as potent, and visually smarter than ever.

In an 11-year life at Wellingborough, it made something like 39,000 YB-based engines. It’s still very much the stalwart of the fast Ford scene to this day.

Ford Cosworth YB Tuning Guide

Cosworth Engine Block

There are two main types of Cossie block – known as the 205 and the 200. The latter is a thicker-wall design and was found in 4×4 versions, such as the Escort and 1990 Sapphire. These are easily identified by the numbers cast on the side. Although, to confuse things further, the RS500 block was a thick-wall design but stamped 205. It’s recognizable by its smaller core plugs.

If you want moderate power up to around 350-to-400bhp then either is fine. Although good quality fasteners and gaskets are a must for any YB block. But for anything more powerful you should ideally be starting out with the 200 block. The extra material within the block, in particular at the base of the cylinders, makes fitting long studs rather than head bolts an option. This can help improve the sealing between head and block, and ultimately aiding reliability.

For most engines sub-500bhp, six long studs will be adequate. The center six, with the closest and furthest fixing retaining the original length bolts or studs. But mega-power engines (or those used in harsh race conditions) will usually feature all ten long studs. This is to allow for even more clamping force. This requires additional machining; the water pump needs modifying to avoid clipping the newly fitted studs at the front end.

Liners

Along with long studs, almost all big-power YBs will feature Nikasil-coated steel liners. These are stronger, have better oil control, and offer less friction than the original bore.

There are two types of liner: dry or wet. Dry liners are 3mm thick and are sleeved into the original bore. Wet liners are thicker at 6mm. They are so-called because the extensive machining to get them to fit means none of the original bore remains and the new liner encroaches into the block’s waterways.

Liners and studs are not cheap, though – a fully prepared block will set you back thousands. These days we can also start throwing alloy block options into the mix, which are as strong as the 200 blocks, if not stronger, but are considerably lighter. Smith & Jones Engineering offers alloy blocks in varying bore sizes from standard 90.82mm up to a whopping 96mm, which are available with different deck heights for those looking to lengthen the stroke too.

Working with a new block like this, ARP/Smith & Jones also offer a new ‘though-stud’ design of head stud, which as the name suggests is a stud and nut design that passes all the way through the block and into the crankshaft main caps, therefore tying the whole engine together from top to bottom.

Costing around £3500 for a bare block (before you add options like piston cooling jets at £150, and the through studs at £650) they’re normally reserved for the biggest of builds and aren’t commonly found in road cars. But they are the foundation for some of the most powerful YB engine builds we’ve seen.

Cosworth Engine Internals

The factory internals of the YB are actually very good, especially the stock cast steel rods (much better than most OEM cast iron rods) are proven to cope with 500bhp. The only criticism is that they are a bit on the short side. Therefore, to free up a bit more power (as much as 10bhp in some cases), many tuners opt to fit longer con-rods – usually 136mm as opposed to the standard 128mm items.

Doing so makes the rod angle more favorable, meaning that when the crank rotates, the rod doesn’t travel through such a steep angle and forced out of the cylinder wall, but is instead being pushed upwards into the cylinder.

The stock crankshaft is also very capable as standard – it can cope with most things thrown at it and is only really changed when stroking the engine to a larger displacement. There is one caveat, though – if it has been ground down a size or two it’s best suited to sub-350bhp applications. With the prices of standard-grind cranks on the rise (we’ve seen sellers asking as much as £1500), the price gap between a second-hand original and a new aftermarket item is ever decreasing.

Pistons

YB pistons are particularly well engineered as standard, and work well on 400bhp engines many times over. But when altering the compression ratio or using valve cut-outs (needed for engines running anything more aggressive than BD10 cams) the machining costs can add up. Therefore, many engine builders opt for a set of forged pistons made to their exact required specification instead.

On the subject of compression ratios, 7.5:1 and 7.2:1 used to be the norm in high-boost applications. But with the advent of better engine management, improved gasket designs, and greater clamping force offered by stud-and-nut kits, many tuners are taking advantage of them to maintain a higher compression ratio – in some cases actually increasing it from the standard 8.0:1 to over 9.0:1.

Cosworth Turbo and Exhaust

The turbo dominates the YB like a massive chili on a tiny pizza. Many people think it is the business end of the engine. In reality, it is just another component part of the entire YB package. As such, needs to be carefully considered to work with everything else in the engine when tuning.

The standard Garrett T3 found on the Sierra and Sapphire Cosworth is good enough to see you with around 300bhp, and specialists like Turbo Performance can make use of tricks like cut-back blades, and 360-degree thrust bearings to help improve performance of the OE unit.

But the traditional upgrade is the Escort Cosworth’s larger T34 turbo, capable of 350-to-400bhp with the right optimisation. Because they are all based on the same Garrett T3 core, specialists like Turbo Performance can actually pick-and-mix housings to create a T34 with the T3’s smaller 0.48 exhaust housing, for example, to provide greater peak power than a stock T3 but with less lag than a stock T34.

From there a T38 hybrid will see you well into 400bhp power figures, and an even bigger T4-based turbo from the RS500 will take you the rest of the way up to 500bhp.

Newer turbos

These upgrades work time and again with great results, but with the development in technology and newer turbos now available, the choice has opened up even further. Garrett’s roller-bearing GT range of turbos have been used to great effect on the YB, and the new BorgWarner EFR series of turbos are showing very impressive results in terms of power and, thanks to their twin-scroll design, driveability and quick spool-up too.

With so many options available, turbo choice is virtually endless, and it is best left to the experts to decide what will work best for a given application.

The good news, though, is that the YB’s exhaust manifold is of a twin-scroll design as standard, so is ready to accept a twin-scroll turbo without too much fuss. Bigger turbos often require a larger mounting flange, however, so it’s often worth upgrading to a tubular exhaust manifold at the same time. Doing so also makes installation of an external wastegate easier too, which many tuners prefer over the OEM-style internal wastegate, to offer more accurate boost control.

Cosworth Engine Inlet and Injectors

On the opposite side of the engine to the turbo, inlet manifold choice has also improved drastically over the years. To start with, the RS500 eight-injector manifold was a must, then the ‘Swedish-style’ inlet was everyone’s fancy, and now nearly all big-bhp YB builds feature a Hart inlet.

There are slight differences in performance between them, but all that really matters is that they all perform much better than the standard inlet, which becomes a restriction at around 500bhp. Roller-barrel throttles have also been used to good effect in many applications, but as they were only ever designed to work on 300bhp WRC cars, when you start to push enough air for over 500bhp through them they don’t always like it. Another option is to fit a set of individual throttle bodies. Used with a plenum chamber, these will have performance advantages. Considering a single throttle body gives such good results, only use when looking to squeeze out every last bhp possible.

Sizing up

The traditional route of replacing injectors was to go for the next size up in the Bosch range. The first step is dark greens or 803s, capable of 300-to-330bhp, costing around £320 as set from trusted sellers such as Motorsport Developments. Continuing up, the colour-coded Bosch items are ‘light-blues’ or 400s, which are good for up to 400bhp, then ‘greys’ or 403s, which supply the juice for 400-to-450bhp.

Sticking with the Bosch injectors but wanting more than 450bhp involves simply adding more of them – another four, in fact. This utilises the RS500’s or WRC-style eight injector setup. Eight greens will provide enough fuel for over 500bhp Eight greys are suitable for ultimate power.

Today, sophisticated modern engine management and improved injector designs mean you can buy items that will deliver over twice as much fuel as a set of greys. As a result, there’s no need to add the complexity and expense of an eight-injector setup. Traditionally, larger injectors were more difficult to control at lower engine speeds. Therefore, two sets of smaller injectors were the preferred method of ensuring low-speed driveability coupled with peak power potential. Now, modern injectors/ECUs are more capable of delivering at both ends of the scale, so offer a neat and simple alternative.

Cosworth Engine Head and Cams

Designed to go racing, the top end of the YB engine is impressive in stock form too. For a stock head, 350bhp is no problem. But at around 500bhp the ports start to become a bit of a restriction. As standard, the inlet ports are 22.5mm and the exhaust ports are 23mm. Opening these up to around 25mm and 24mm respectively will be good enough for 500bhp while retaining standard valve sizes. For even more power, increase the port sizes to 26/27mm and 25/26mm. Remember, you’ll also need bigger valves to make the most of them.

As for camshaft options, this will usually depend on what the engine is built for – there are many off-the-shelf profiles to choose from, and many engine builders have cams ground to their specific requirements too. Top-end engines will be running ‘custom spec’ profiles (closely guarded secrets), and some are so aggressive they actually require the head to be machined in order to fit them; the lobes are so big they physically won’t rotate within the confines of a standard head.

But for 500bhp engines there are plenty of options. Generally, a BD10 inlet with standard exhaust cam is the first-stage upgrade and works well on a variety of engines, but BD14 and BD16 combinations have also been used to good effect, while some tuners swear by the profile offered by an AB07 cam. As with turbo choice, the cam profile needs to be chosen to work with the rest of the engine spec, so leave this to the engine builder to decide.

Ford Cosworth YB Engine Management

Long gone are the days of a simple Stage 3 chip. Nowadays, with massive advances in technology we expect a lot more refinement, even from the standard ECU. Features such as closed-loop lambda control, wasted-spark ignition, and the ability to live map have made big improvements. These are ideal for fast-road applications. On top of these there is now a wealth of standalone, aftermarket ECU systems to choose from. All of which are more than capable of running a YB engine.

It is also worth noting that one major factor in changing to an aftermarket ECU these days is not just because of the additional mapping features, but because it also replaces the standard wiring loom. Something that, now it’s all old and crusty, can cause major problems on a Cosworth. Thankfully, companies like Auto Dynamix offer OEM-style replacement wiring looms, or bespoke items to suit your specific setup.

Modern ECUs also allow tuners to take full advantage of several advances in engine management design since the YB was first introduced; things like coil-on-plug ignition, knock detection and electronic boost control all help aid reliability and performance. While extras such as launch control, full-throttle gear shifts, and anti-lag systems all add to the grin-factor too.

Ford Cosworth YB Engine Codes

A Ford Cosworth YB engine is a Ford Cosworth YB engine, right? Wrong. There were actually 20 different versions of the legendary Ford Cosworth YB Cosworth engine over the years, and here’s what they were…

Code Year Description

YAA 1983 Original aftermarket naturally-aspirated, 16-valve conversion for Pinto

YAB 1984 First turbocharged version of YAA

YAC 1990 Naturally-aspirated version of YBG for kit cars, with carbs

YBA 1984 Modified version of YAB

YBB 1985 Series-production Sierra Cosworth engine

YBC 1985 Race version of YBB

YBD 1987 Series-production Sierra Cosworth RS500 engine with big turbo

YBE1A 1987 Version of YBB for Ford Industrial Power Products, used in the Panther Solo

YBE2A 1989 Version of YBG for Ford Industrial Power Products, used in the Panther Solo

YBF 1987 Race version of YBD/RS500 engine

YBG 1989 ‘Green’ version of YBB used in Sapphire Cosworth 4×4 (US83 emissions)

YBG (GrpN) 1992 Race version of YBG

YBJ 1989 ‘Green’ version of YBB used in Sapphire Cosworth 4×4 (15.04 emissions standards)

YBM 1989 Race version of YBG and YBJ

YBP 1994 Small-turbo Escort Cosworth engine – fitted with EEC-IV management (launched 1994)

YBR 1990 Ford rally engine for use in Sapphire Cosworth 4×4

YBS 1990 Ford rally engine, Group A rally kit, parallel to YBR

YBT 1992 Escort RS Cosworth big-turbo road engine (rally cars also used engine code)

YBT (GrpN) 1992 Race version of YBT engine

YBV 1992 Methanol-fuelled 2.3-litre version of YBM for racing in America

The post Ford Cosworth YB Engine Guide & How To Tune It appeared first on Fast Car.