The new sunroof is based on PDLC (polymer-dispersed liquid crystal) technology

Seven-layered Solarbay sunroof will be available on Scenic and Rafale, with strong focus on sustainability

Before almost every car became available with air conditioning in the UK, sunroofs were the popular, must-have accessory.

Apart from helping with ventilation, people like the feeling of open space they give as a kind of halfway house to a convertible, and they’ve remained popular.

Traditional mechanical sunroofs have plenty of drawbacks, though, some of which are becoming unacceptable in today’s sustainability-driven world. One is weight.

On a powered sunroof, the materials, guide rails, electric motor and shutter system can add 6kg-8kg at the highest point of the car, where, as well as being a CO2 burden when manufacturers are trying to lose every gram, it’s not great for handling. Squeezing in the roof panel and gear also takes up about 30mm of head room.

An alternative is a fixed glass sunroof that can be dimmed with a button touch or a swipe, thanks to layers sandwiched in the glass that react to an electric current.

Although various technologies have been around in luxury brands for a few years, Renault thinks it will be the first mainstream manufacturer to offer its own version of the technology in the new Scenic and Rafale, which will go on sale next spring.

The new fixed glass sunroof, called Solarbay, is based on PDLC (polymer-dispersed liquid crystal) technology. Occupants can darken the glass in segments using switchgear in the overhead panel or voice control via Google Assistant.

The panel darkens in nine bands across the glass, emulating a blind being drawn from front to rear or (and Renault says this is unique to its design) rear to front, so front and rear passengers can choose to be in sunlight or a closed cabin independently of each other.

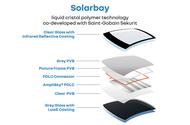

The glass itself is a seven-layer lamination of several materials. Starting from the top, the first is clear glass with an infrared reflective coating.

Next is a grey film of PVB (polyvinyl butyral), which is the basic lamination used in laminated glass to retain shards if a pane is shattered. Beneath that, there’s another picture-frame PVB layer to form a graphic visual frame around the sunroof. And below that are the two active elements.

The first is the PDLC electrical connector, forming a rectangle all around the sunroof, and below that the Amplisky PDLC layer, then another layer of clear PVB.

Finally there’s a panel of grey glass with a ‘low-e’ coating, forming the sandwich. Low-e coatings are a ‘low emissivity’ material, which means they don’t readily absorb heat from the sun and nor do they release heat from inside the cabin.

The roof is controlled by its own ECU, which is independent of the glass, so if either fails or is damaged, it can be replaced independently.

Renault says the roof has been developed with a close eye on sustainability. Half of the glass is from recycled waste plate glass and automotive production and 90% of the roof, including the PVB and PDLC, can be recycled at the end of its life.